1. Waste from Overproduction

• This creates more products than needed at a point in time.

• Often it is caused by fear of running out.

• However, producing more than "just enough" or "just-in-time" inventory drives up the costs of inventory and results in scrap if demand does not equal supply ¡ª wasting all the value if the excess products must be scrapped or sold at a loss.

• Often considered the worst of the seven wastes because it encompasses the rest of the wastes, often this is caused by quality problems.

2. Waste of time in Waiting

• Waiting is the waste of people's time when they have to wait for a part, materials or information they require to perform their work or make decisions.

• Mostly they are waiting for one another, which often happens because they have non-aligned objectives.

3. Transportation / Conveyance Waste

• This is the unnecessary movement of products, materials or information.

• The things necessary to do the job should be at hand so you don¡¯t have to go get them or take them to where they are needed.

• Factory layouts often can be the fundamental cause of excess transportation.

• When appropriate, re-laying out the machines within a factory from a functional to a cellular layout has been found by many companies to help not only reduce transportation waste ¡ª but also reduce WIP and waiting.

4. Over Processing waste

• Muda occurs when a step in the process does not add value as perceived by the customer and thus causes you to examine which of your processes ¡ª or even products ¡ª are necessary.

• Do the customers really care about a particular product feature and your company simply hasn¡¯t figured that out yet?

• Do not use more energy or activity than is necessary to produce a product.

• Likewise, do not add more value than customers are willing to pay for.

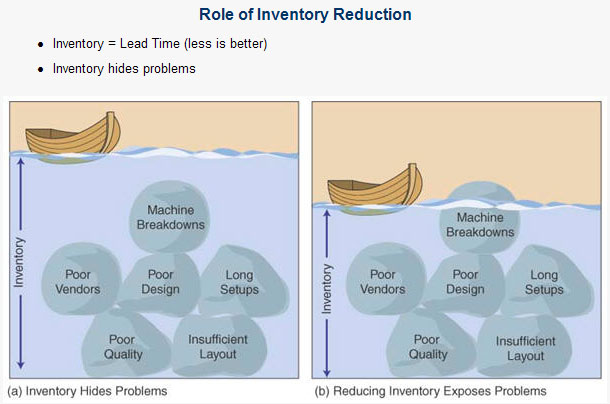

5. Inventory waste

• Always a tough one for accountants, inventory is well known as a cost item.

• Finished products, parts and supplies kept in inventory are pure cost, not value; they add additional cost by requiring space, additional facilities and equipment to handle and move them, and they can become scrap if they exceed shelf life or are of no demand.

• The true cost of excess inventory levels should be analyzed carefully before you order excess raw materials simply because the purchase price is less.

• Many companies order over and above what is required to fulfil the order, perhaps partly due to quality problems along the production process or the often-mistaken belief that it saves money by ordering larger quantities.

• Just-in-time inventory and lean manufacturing can eliminate such unnecessary costs by matching production to demand in real time to eliminate the need for excessive inventory, warehouse and equipment space, etc.

6. Waste of motion

• The unnecessary movement of people ¡ª such as

walking,

lifting,

reaching and

stretching

can be cut down via simple ¡°good housekeeping,¡± effectively reducing wasted movement.

• 5S is a technique used by many companies to focus effort on keeping the workplace tidy, with unused materials and machines disposed of so as not to create unnecessary clutter and therefore searching.

7. Waste from product defects/ Correction

• Caused by quality-related issues, manufacturing has costs of scrap and rework when processes produce defects.

• Defects cause rework, confusion and upset a synchronized set of processes

• It takes less time to make something right than it does to make it poorly only to have to correct it later.

http://syque.com/improvement/Muda.htm

http://news.thomasnet.com/IMT/archives/2006/04/7_plus_sins_of_muda_waste_not.html?t=archive » More Information